Biogas plants

Biogas is the gas that is released from the fermentation of biomass. It is a colorless and odorless substance that is 70% methane and 30% carbon dioxide. It has a very high heat output: when burning 1 m³ of biogas, the same amount of heat is released as when burning 1.5 kg of hard coal. Getting biogas is not the only purpose of a biogas plant. An important factor is that the main raw materials for its work are organic waste from the food industry and agriculture. Often, the removal and disposal of such residues of production is costly. Waste disposal in biogas plants brings not only environmental benefits, but also a positive financial effect. Biogas from the plant is burned in cogenerators to produce heat and electricity, which increases the company's income.

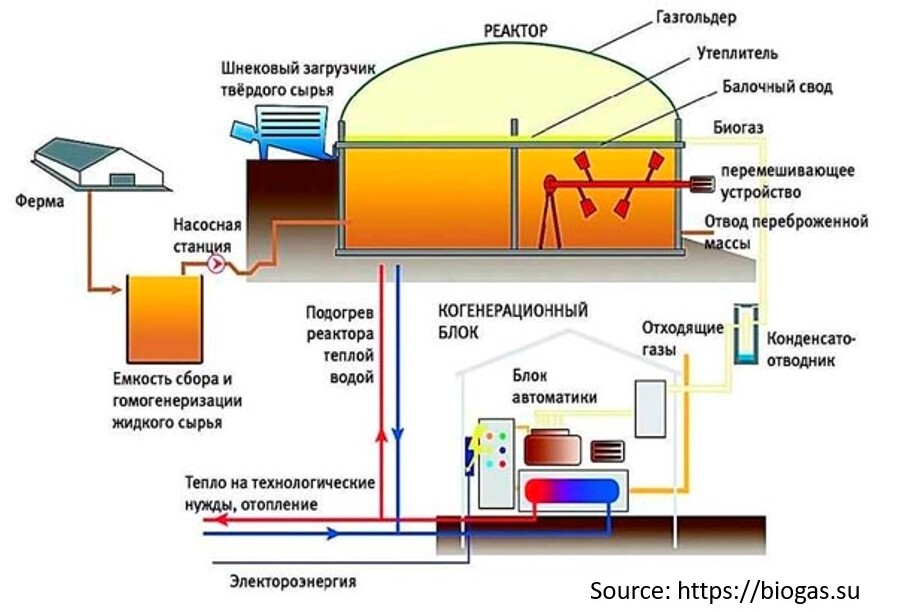

A biogas complex is a complex engineering facility that consists of several modules combined into a single system. Below we provide an indicative list of equipment and subsystems that, in one or another combination, are part of a biogas plant.

- Substrate (biomass) storage system.

- Module for weighing and supplying dry types of substrate.

- Liquid substrate loading module.

- Fermenter and conditioner.

- Substrate heating system (temperature support).

- Mass transfer system in the fermenter (mechanical, hydraulic or bubbling mixing).

- Gas tank and gas facilities.

- Biogas purification system.

- Cogenerator.

- Separator for separating the liquid and solid fractions of the spent substrate (obtaining liquid and solid organic fertilizers).

- Digestate storage tanks (lagoons).

- Control point for the operational management of the biogas plant.

- Laboratory for monitoring the characteristics of the substrate.

- Switchboard.

- Pumping station.

- Sanitary facilities for staff.

When designing and selecting equipment, the type of raw materials used and the ultimate goal (production of thermal energy for own needs or production of electricity for the purpose of sale), as well as the characteristics of raw materials and production, are taken into account.

The raw material (animal manure or other usable organic material) is fed into the raw material collection tank. From this container, it enters the bioreactor (methane tank), which is a sealed vessel. In the digester, the raw material is heated to the desired temperature, which is set depending on the type of fermentation chosen. It also creates the necessary pressure. Under conditions of complete anaerobicity and the absence of light, organic matter decomposes, followed by the release of biogas. Biogas is accumulated in a storage (gas tank), then it passes through a purification system and is supplied to a cogeneration plant that produces heat and electricity. The spent mass is removed from the reactor and is a ready-to-use organic fertilizer.